- Call Us: 9900067486

- info@Sciefi.in

B-378/1, Ring Road, 1st Stage, Peenya,(near TVS cross), Bengaluru – 560058, India

Call Us: 9900067486

Monday to Friday Saturday and Sunday are not working days.

(09.30am - 05.00pm)

Our 24-day basic pipe stress analysis training is designed to equip students and professionals with essential knowledge and skills in piping design and piping engineering, focusing on real-world applications in industries like oil & gas, power plants, and chemical processing. This piping engineering course provides a blend of theoretical learning and practical problem-solving, ensuring that participants gain a comprehensive understanding of pipe stress analysis principles.

24 Days

Certification provided upon completion

Offline, instructor-led classroom training

Suitable for mechanical engineers and professionals with a background in piping design course or related fields

Understand the fundamentals of piping systems, including the purpose and function of pipes in various industries.

Learn how to interpret essential engineering drawings related to piping systems, such as:

1.Isometrics: Detailed drawings showing pipe runs and connections.

2. Plant Layout: Overview of the piping system within an industrial plant.

3.GA Drawings: General arrangement drawings showing equipment and piping layouts.

Explore various pipe support systems and their significance in stress analysis. Learn how to choose appropriate supports for different systems..

Understand how boundary conditions affect pipe behavior under stress and how to apply these in analysis.

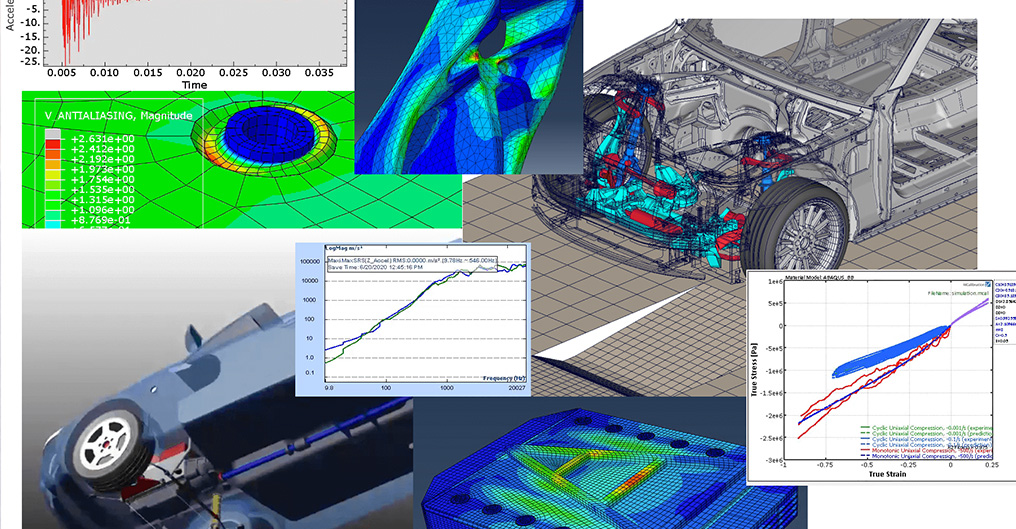

Study the different types of loads acting on piping systems, including weight, pressure, thermal, and occasional loads such as seismic or wind.

Learn how to analyze piping systems under static loads like pressure and weight.

Understand how to evaluate systems subjected to dynamic loads, including thermal expansion and vibration.

Numerous example problems are provided during the piping course, covering real-world scenarios faced by piping engineers.

In this piping engg course, you’ll get the opportunity to work on independent problem-solving tasks, reinforcing your knowledge through practice.

Tests are conducted after each stage of the training to ensure that you grasp key concepts and are progressing effectively.

The curriculum is designed to meet the needs of industries that rely on CAE, ensuring you learn practical and up-to-date techniques.

Our instructors are industry veterans with extensive experience in using Hypermesh for real-world projects. They provide personalized guidance and mentorship throughout the course.

Typically, a Bachelor’s degree in Mechanical, Civil, or Chemical Engineering is required. Specialized certifications and training in piping design software, materials, codes (like ASME, ANSI), and project management may also be needed.

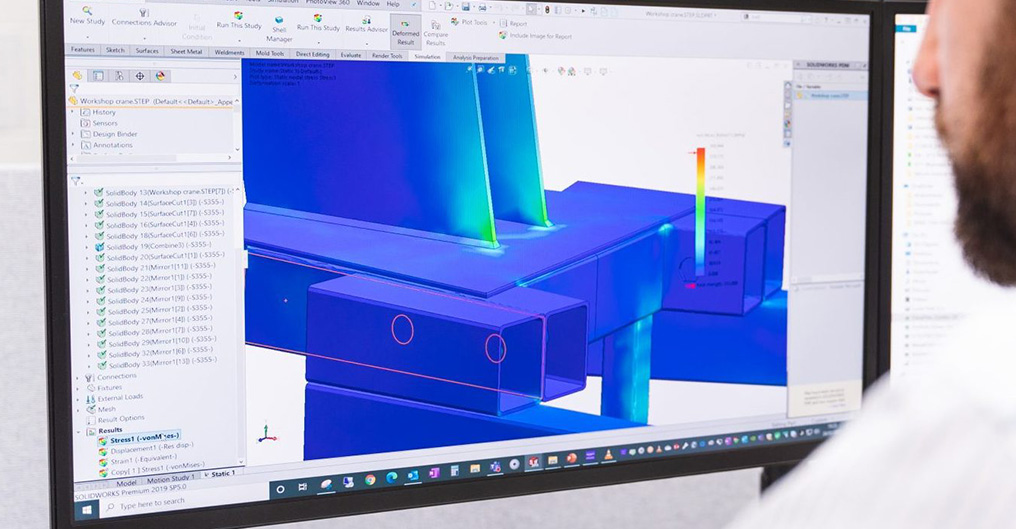

Pipe stress analysis is a technique used to determine the strength and flexibility of a piping system, considering factors like internal pressure, temperature variations, and external loads. This analysis helps ensure that the system can withstand operational stresses without failure.

A Piping Material Specification (PMS) defines the materials and components for the piping system, specifying pipe dimensions, material types, pressure ratings, temperature limits, and corrosion resistance requirements.

Upon completing the training and passing the final assessments, you will receive a certification that validates your proficiency in CAE and Hypermesh, boosting your employability and career prospects.